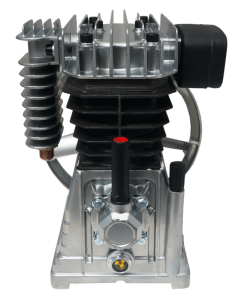

HIGH PRESSURE 2 STAGES COMPRESSOR PUMP 42CFM 175PSI 13BAR CASTIRON MADE 10HP

- Cast Iron made twin heads 2 stages high pressure compressor pump

- Model: VZ2105T

- Type: 2 Stages High Pressure Air Compressor Pump

- Motor Suits: 7.5KW/10HP

- Air Receiver Size: 150L TO 250L

- Pump Displacement: 1100L/min at 760rpm / 42cfm

- Bore x Stroke: 105mm x 2 + 55mm x 2

- Pressure: 175 PSI / 13 BAR

- Flywheel Diameter: 400mm DOUBLE Grooves

- Dimensions: 620 x 630 x 610mm

- Shipping Dimensions: 750 x 650x 650mm At 92KG

Air Compressor Pump

$1,226.83

| Weight | 27 kg |

|---|---|

| Dimensions | 49 × 32 × 40 cm |

DESCRIPTION

Single Stage vs. Two Stage Air Compressor

The main difference between single and two stage compressors is the number of times that air gets compressed between the inlet valve and the tool nozzle. In a single stage compressor, the air is compressed one time; in a two stage compressor, the air is compressed twice for double the pressure.

Single stage compressors are also known as piston compressors. The process that takes place within a single stage compressor goes as follows:

- Air is sucked into a cylinder

- The trapped air is compressed in a single stroke with a piston at roughly 120 psi

- The compressed air is moved onward to a storage tank

In the storage take, the compressed air serves as energy for the assortment of tools that a single stage compressor is built to accommodate.

The process within a two stage compressor — alternately referred to as a dual stage compressor — is similar to that of a single stage, but with one variation: the compressed air isn’t sent to a storage tank; it’s instead sent to a smaller piston for a second stroke, this time at roughly 175 psi. From there, the double–pressurized air is cooled and delivered to a storage tank, where it serves as energy for vast arsenals of high–powered equipment.

People who are new to air compressors will often confuse the number of cylinders for the number of stages in an air compressor, when in fact both single and two stage compressors use two cylinders, because it’s easier to balance air that way. The difference between the two stage air compressor vs. single stage in this regard is that, in the latter, both cylinders are the same size. On the other hand, in two stage compressors, the second piston is shorter than the first, and the two are linked by a cooling tube, which brings the temperature of the air down before the second round of compression.

There are no reviews yet.