TIYI FRL Filter Regulator 1/2” Air Source Processor Pressure Regulator

- Features:

- Pure copper filter core, better filtering, longer service life.

- Filter adopts novel vane design with high division efficiency and differential pressure discharge device.

- Regulator valve adopts balanced inlet structure with the advantages of stable pressure, high precision, and quick reaction.

- Help filter liquid and foreign particles from compressed air line, widely used for pneumatic tool and components.

Air Compressor

$127.60

- Description

- AIRLINE FILTER & FRL

- CHOOSING A FILTER FOR COMPRESSED AIR

- PAYMENT POLICY

- SHIPPING POLICY

- RETURNS POLICY

- CONTACT DETAILS

- Reviews

Specification:

Model : 40-TAW4000-04

Operating Fluid : Air

Material : Metal, Plastic

Joint Pipe Bore : G1/2″

Max Pressure : 1.0MPA(10.0bar)

Adjustable Pressure Range : 0.05-0.85MPa(0.5-8.5bar)

Operating Temperature Range :0°C -60°C

Pressure Gauge Range : 0-1MPa, 0-10kgf / cm2

Flow Rate L/min: 4000

Relief Pressure: Set Pressure + 0.5 BAR (relief flow rate of 0.1 L/min)

Filtration: 5µm

Package Content:

1 x Pneumatic Filter Regulator

1 x Pressure Gauge

1 x Install Stand

AIRLINE FILTER & FRL

AIRLINE FILTER

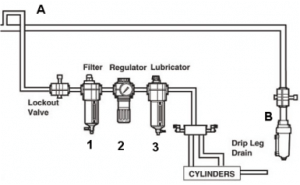

An airline filter cleans compressed air. It strains the air, traps solid particles (dust, dirt, rust) and separates liquids (water, oil) entrained in the compressed air. Filters are installed in the air line upstream of regulators, lubricators, directional control valves, and air driven devices such as cylinders and air motors.

Because airline filters remove contaminants from pneumatic systems, they prevent damage to equipment and reduce production losses due to contaminant-related downtime. Downtime in an industrial plant is expensive; often it is the result of a contaminated and poorly maintained compressed air system.

Selecting the proper size of filter for any application should be done by determining the maximum allowable pressure drop, which can be caused by the filter. The pressure drop can be determined by referring to flow curves provided by the manufacturer.

PRESSURE REGULATORS

Pressure regulators reduce and control air pressure in compressed air systems, including rotary screw air compressors. Regulators are also frequently referred to as PRVs (pressure reducing valves).

Optimally, a pressure regulator maintains a constant output pressure regardless of variations in the input pressure and downstream flow requirements. In practice, output pressure is influenced to some degree by variations in primary pressure and flow.

Pressure regulators are used to control pressure to:

Air tools

Blow guns

Air gauging equipment

Air cylinders

Air bearings

Air motors

Spraying devices

Fluidic systems

Air logic valves

Aerosol lubrication system

Most other fluid power applications

General purpose regulators are available in relieving or non-relieving types. Relieving regulators can be adjusted from a high pressure to a low pressure. Even in a dead-end situation, relieving regulators will allow the excess downstream pressure to be exhausted. This causes a loud hissing sound which is perfectly normal.

Non-relieving regulators that are similarly adjusted will not allow the downstream pressure to escape. Instead, the trapped air will need to be released in some other way—for example, by operating a downstream valve.

Downstream equipment flow and pressure requirements must be determined to properly size the correct regulator for the application.

CHOOSING A FILTER FOR COMPRESSED AIR

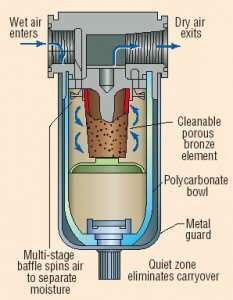

Reliability is one of the strongest reasons to use compressed air, and proper filtration is the key to maximizing reliability and longevity. Compressed air can carry condensed water, oil carryover from compressors, solid impurities (pipe scale and rust) generated within the pipelines, and other wear particles from the ambient air. These contaminants can cause problems at every point of use, and should be removed by installing suitable filters.

Contaminant particle size is measured in micrometers (µm), which each represents one-millionth of a meter or 0.000039 of an inch. Filters are rated according to the minimum particle size that their elements will trap. Although filters rated at 40 to 60 µm are adequate for protecting most industrial applications, many point-of-use filters are rated at 5 µm. Note that finer ratings increase the pressure drop through the filter, which equates to higher energy cost to compress the air.

In addition, finer filters clog more rapidly, also increasing pressure drop. (In other words, while filters finer than necessary do no harm to downstream components, they will have a negative impact on air system operating cost.)

PAYMENT POLICY

- PayPal

- PayPal account email address (to receive payments): [email protected]

- Bank Deposit

- buyers will see the bank account number in checkout

- Pay on pick up at our counter

SHIPPING POLICY

1. Our orders are usually shipped within 24 business hours after payment received unless there are problems with the order. If this is the case we will contact you via your eBay email address or telephone number. So please double check with the number you have left on eBay as this is mandatory for courier shipping purpose.

2. Orders are normally processed each working day not including weekends. Usually if your payment is received after 2:00 P.M. or on the weekend, it is processed on the next business day.

RETURNS POLICY

1- All our products come with 1 year warranty, unless stated otherwise. Stated clearly on the tax invoice.

2- All warranty/return items must accompany by a return approval (RA) note. Please contact us via email, or telephone to obtain a return approval.

We do this to minimize errors and misunderstanding.

3- Any item returned without an RA note will not be looked at or contact and would eventually be discarded. This will cause delay to your warranty claim.

4. We will not be responsible for any loss incurred by the buyer sending an unmarked item to our store. The Buyer will need to bare all costs in processing the returned item.

CONTACT DETAILS

Add:28 Aristoc Rd, Glen Waverley. Vic. 3150

(We are opposite of Monash Aquatic & Recreation Centre. Left entry of the building)

Mobile: 0401 634 280

Phone: (03) 8555 2518

https://www.cononmotor.com.au (online store web)

E-mail: [email protected]

[email protected]

There are no reviews yet.